With the development of science and technology, computer technology and Internet technology gradually integrated with measurement technology, making measurement technology gradually towards the development of automation and intelligence.

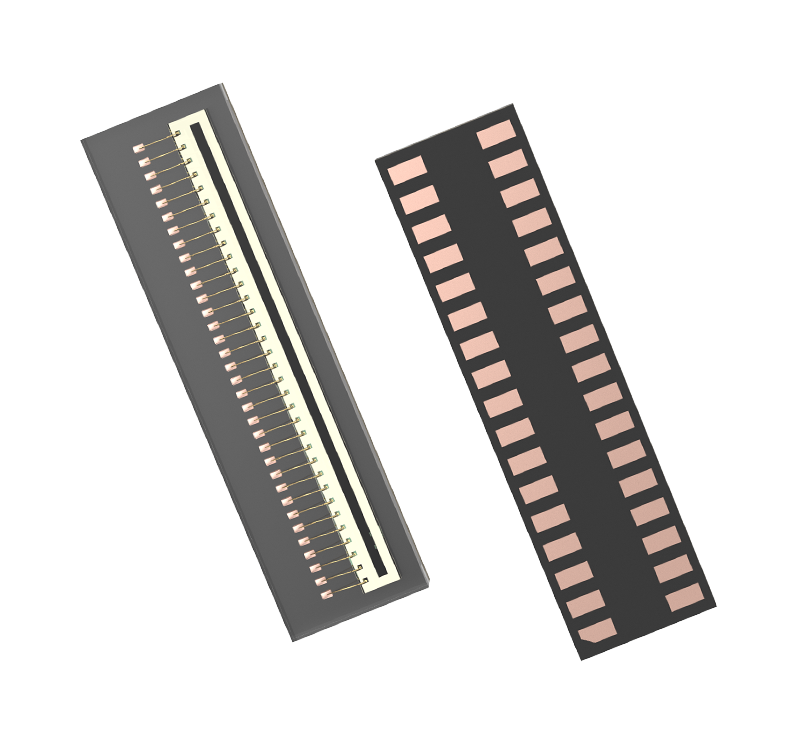

Laser calipers, as products using measurement technology, can be used for non-contact measurement and control of object dimensions, such as part height, edge, diameter, line diameter, width, gap, inner diameter, outer diameter, etc. The use of PCI micro-optical imaging sensors (with clear dark light imaging, high distance measurement accuracy, rapid response, etc.) in laser calipers can effectively reduce the cost of single product inspection after production and can save the loss of raw materials and reduce personnel requirements.

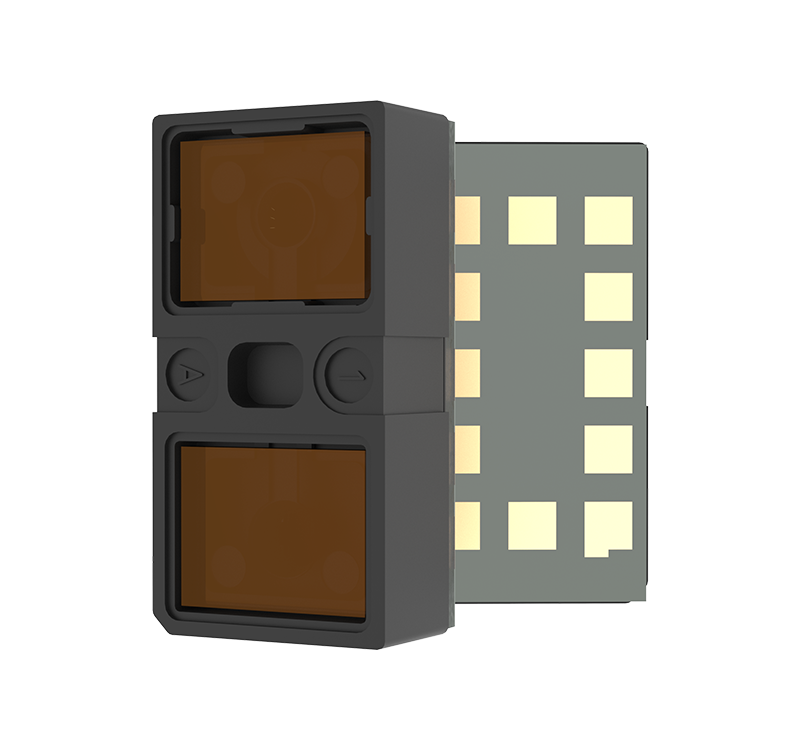

A photoelectric switch/safety light curtain is a photoelectric safety protection device, mainly used in industrial production, and is a kind of safety protection role of automatic control products.

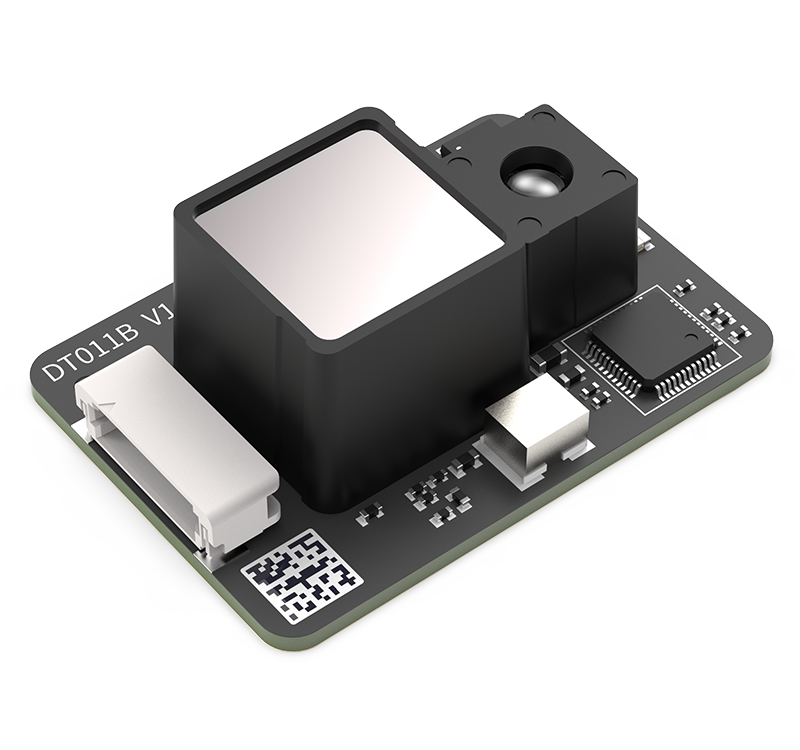

The photoelectric switch/safety light curtain products are equipped with dToF sensors, which can accurately detect approaching objects. When a person or object enters the light curtain barrier area, the control system quickly converts the output level signal to produce a load action so that the machine stops; when a person or object leaves the warning area, the load function automatically turns off, thus achieving the purpose of safety protection.

As spatial three-dimensional coordinate machines with biological functions, robots play a punctilious role in replacing or assisting humans in their work.

With the research and further development of AI, robotics, and automation control systems, machine vision technology, known as the "eye" of robotics, is receiving more and more attention. Machine vision technology uses light sources and sensors to acquire images of inspection objects and extract information from the images to detect, measure, locate, and identify objects instead of the human eye.

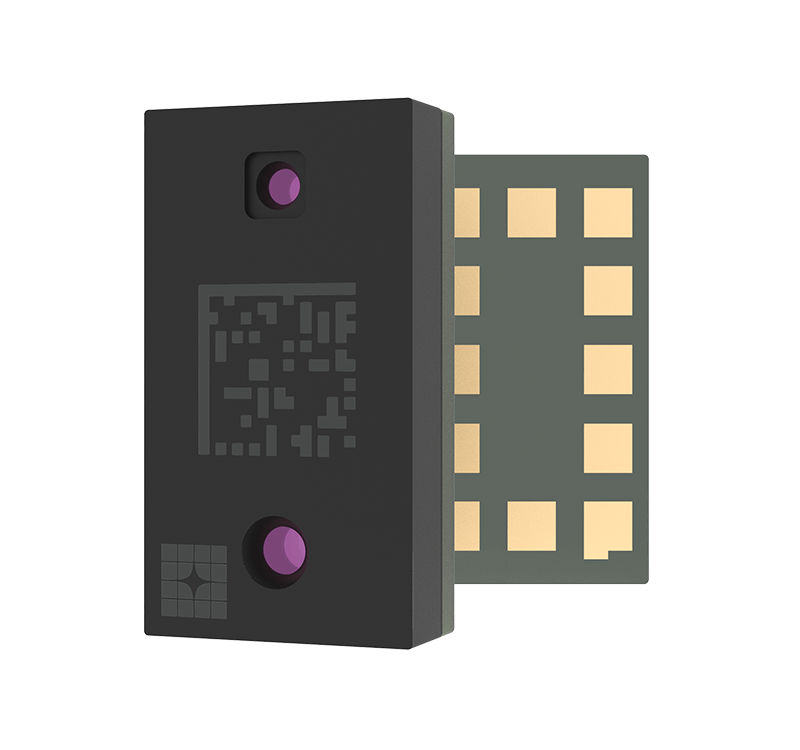

As an excellent choice for robotic vision sensing, dToF sensors can help robots with navigation, obstacle avoidance, gesture/motion recognition and proximity detection, making home delivery, meal delivery to the table, and help with household chores, which once existed in people's imagination, a science fiction story, a reality.

AGVs are widely used in logistics and warehousing, as well as in flexible production lines. dToF sensor technology plays a very important role in obstacle avoidance, collision avoidance, and safety protection for AGVs.

PolarisIC's self-developed dToF depth sensing sensor has the advantages of high measurement accuracy, long effective detection distance, low power consumption, and strong anti-interference ability, which can be widely used in AGVs and can effectively improve the operation efficiency and guarantee the safety of AGVs.

In some scenarios of factory automation devices and capacity management, dToF sensors need to be applied to monitor the placement capacity of supermarket containers and warehouse goods.

As automation devices are used more and more extensively, the accuracy of sensor measurements is required. Loading dToF sensors in these scenarios enables long-range, accurate, ultra-high-speed ranging, which can reduce manual monitoring activities, accurately measure capacity, and effectively improve the efficiency of personnel and management deployment.